Behind the maintenance problems that accompany truck ownership is an even bigger dilemma: the upkeep of truck bed Winterizing Tonneau Cover and tonneau cover in the winter months. While its well-installed tonneau cover carries its weight during the year, the frigid temperatures, snow, and possibly ice would add havoc to the cover. True wintering means the cover would slide with ease, not incur injuries, and last a considerable length of time. This winterizing guide for tonneau covers indicates relevant steps that every truck owner should undertake before the onset of winter.

Check Cover and Seals for Damage

The first step of winterizing a tonneau cover is a thorough inspection. Look for signs of wear or damaged panels, hinges, latches, or seals. Rubber seals should be soft and pliable; seals that are hard or torn could let in moisture and freeze inside the truck bed or rust under such freezing conditions. The hinges should be able to move; the cold makes them stiff. A timely detection of possible problems enables their repair before they can affect the performance of your cover during the tough winter months, preventing costly damage.

Cleaning and Lubricating Moving Parts

A clean tonneau cover will be more easily maintained and prepared for wintertime use. Remove debris, dust, and dirt from the panels and hinges. Pay special attention to the folding mechanisms, as trapped debris tends to become frozen with the low temperatures and will prohibit movement. After that, the manufacturer-recommended lubricants for moving parts should be used to lubricate the hinges and latches. The right lubricant will allow easy operation even at freezing temperatures and will keep metal components from sticking or bending from pressure. The preventative maintenance required on the cover during winter will then include just ensuring that it remains usable until any damage is done.

Prevent Rubber From Freezing

When the truck bed is closed, these seals act to keep water and snow away. When the cold weather strikes, take a silicone-based protector and make sure to apply it to the seals, thereby preventing them from drying and cracking during the cold weather. This application also prevents the seals from sticking to the cover or tailgate at temperatures below freezing. Keeping rubber componentry flexible aids it in sealing against snow, ice, and moisture loaded onto the truck bed by wind. This step will maintain the life of the tonneau cover throughout the winter.

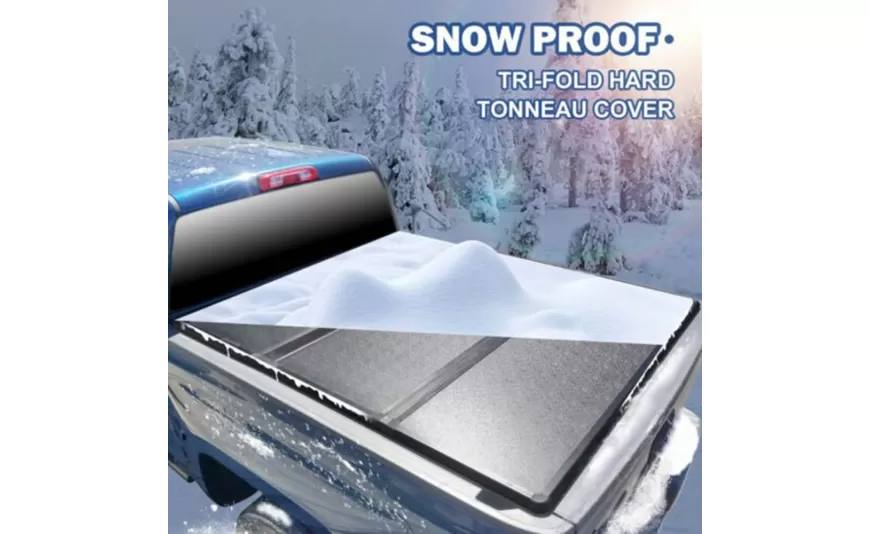

Remove Snow and Ice Regularly

Weight and pressure on the panels and hinges tend to build up by snow and ice accumulated on the tonneau cover. Crusty upper layers of snow on the cover can get stuck and hinder the opening process, thereby damaging the folding parts. To prevent that, simply take a soft brush or broom and wipe off all snow immediately so you don't scratch its surface. Sharp tools or metal scrapers should not be used, as they would scratch the cover material. This method ensures that regular snow removal keeps the cover in good condition, while also allowing for maximum accessibility to the truck bed whenever needed.

Avoid Striking the Cover Hard During the Cold

During cold air temperature, all materials tend to become harshly susceptible to damage from sudden impacts. For this reason, remember that the best care for the tonneau cover during winter is a gentle hold while opening or closing. Do not hit the cover or force it open if ice or frost is present. Gentle handling reduces stress on the hinges and panels and hence prevents cracking or misalignment. One simple habit is all it takes to bestow years to the life of the cover and maintenance of its operability all throughout the seasons.

Store the Cover Properly if Removable

When it's a removable or fully retractable tonneau cover, store it somewhere climate-controlled through the worst months of the year. This will protect it from extreme cold, moisture, and frost accumulation. With proper storage, when the cover is called for, it will be in excellent condition to be installed in spring. If storage cannot be ensured, securing and protecting it from snow, ice, and winds would assist in decreasing its exposure to harsh elements.

Routine Checks of Fasteners and Adjustments

Most metal parts become loose or do not fasten properly during the harsh cold and hot months encountered in winter. Every once in a while, checking all screws, clamps, and mounting brackets would prove useful, ensuring that the cover is neatly secured. Adjustments may be required in order to get those covers to fit and work correctly. An added defense against leaks, rattling noises, and other performance headaches is a cover that is in control of itself. So fastening and aligning proactively during the wintertime makes a tonneau cover big time on your side.

Conclusion

Students for Trucks teaches its members the complete process of properly winterizing a tonneau cover for the protection of the cargo area. Inspect the seals, clean and lubricate the moving parts, keep the rubber parts protected, remove snow and ice, be gentle on the cover, store it properly when removable, and check fasteners for best performance in the cold months. The Winterizing Tonneau Cover Guide will therefore enable the cover to withstand severe OSIAS winter conditions while performing properly in the process of reliable protection for many more years to come after. Winter maintenance, therefore, is not only a precaution but an investment for durability and usability of the truck bed cover.

Tags: Ruibiao Dai

-222x248.webp)

-222x248.webp)

-222x248.webp)

Write a comment